Is Laser Cutting a Cheap Process

GSS Machinery CO2 laser cutting machines provide a wide range of opportunities and possibilities. The versatility, speed, and precision of GSS Machinery laser cutters enables makers, hobbyists, and entrepreneurs to produce everything from a simple machine concept to packaging to trophies & awards. Laser machines can cut wood, paper, plastic, fabric, foam, and much more with such high precision and speed, giving lasers a clear advantage over other types of cutting technologies.

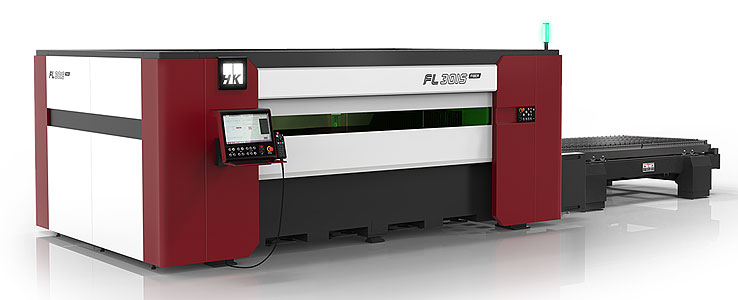

GSS Machinery high speed CO2 laser machines are available in many configurations to suit your needs and budget.